16 Feb Making Predictive Manufacturing a Reality – MicroAI Factory™

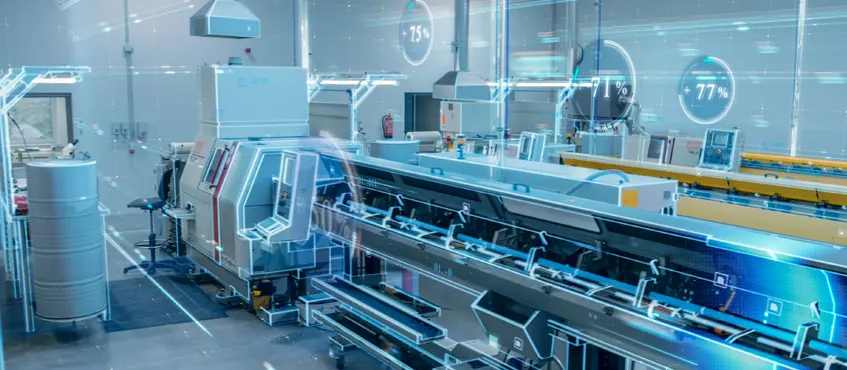

If you have been following the progression of industry 4.0 initiatives, you may have heard the term “predictive manufacturing”. The term has been used to describe a future evolution in which smart technologies would provide manufacturing operations with the power to analyze, predict, and optimize the performance of an entire production operation.

The vision of predictive manufacturing has been impeded by the simple reality that existing AI solutions were not close enough to the manufacturing machines, devices, and processes that they were meant to optimize. This problem was compounded by the inefficient process of sending asset data to the cloud for processing and analysis. A predictive manufacturing ecosystem would not be feasible without further developments in AI and ML (machine learning) capabilities.

The evolution is here, and the enabling technology is Edge-native AI (artificial intelligence). Predictive manufacturing will reshape the manufacturing competitive landscape and be a differentiating protocol in the evolution of industry 4.0.

Manufacturing Intelligence at the Endpoint

MicroAI Factory™ closes the intelligence gap by bringing Endpoint AI and ML to the extreme edge. AI and ML algorithms are embedded directly into a device and machine—typically at the microcontroller (MCU) level. Those algorithms then learn, train, and evolve directly within that specific asset.

Predictive manufacturing combines and harnesses the power of several Edge AI-enabled capabilities to deliver a complete ecosystem of intelligence. MicroAI Factory is the Edge-native AI solution that makes this transformation possible.

How it Works

MicroAI Factory provides a full suite of self-contained Endpoint AI and ML capabilities. By embedding and training AI and ML algorithms directly into the device, machine, or process endpoint, MicroAI Factory provides operators, managers, engineers, and other stakeholders with the ability to improve manufacturing performance as well as predict future trends and to implement forward-looking modifications.

A synopsis of how this works….

- Asset data acquisition: Data is leveraged from a variety of IoT devices and machines. MicroAI Factory is agnostic to sensor values and types. It creates a multi-variant model that utilizes AI inference analysis to generate a wide range of predictive analytics.

- Data storage: Device and machine performance data is synthesized and analyzed locally—in real time. Sensitive data is also stored locally, minimizing the amount of data that is transferred to the cloud. Analytic latency is eliminated and exposure of data reduced.

- Behavioral algorithms: MicroAI Factory utilizes multidimensional behavioral algorithms to produce recursive analysis, training, and processing. This enables a continuous evolution of the Edge-native AI model that takes place directly on the endpoint.

- Analytics and alerts: AI at the extreme edge provides deeper, more intimate, insights into asset health and performance that have not been available with traditional AI solutions. Asset optimization is achieved via intelligence instead of assumptions.

- Data visualization: Presentation of real-time asset performance data via user-friendly, customizable, drag and drop dashboards. Data is customized to meet the specific requirements of various operational and business stakeholders.

What it Provides

Edge-native AI technology brings intelligence to the extreme edge of the business-critical assets within a manufacturing operation. This “edge-of-the-edge” intelligence reduces the costs, security vulnerabilities and inefficiencies associated with cloud-dependent solutions.

With MicroAI Factory, operations can now fully evolve into a predictive manufacturing state that delivers the following features and values:

| Feature | Value |

| Centralized, self-contained, endpoint-based, performance monitoring | Provides real-time device and machine-centric performance monitoring and reporting |

| Edge-native AI embedded and trained into the asset endpoint (MCU) | Provides actionable alerts that mitigate the impact of performance issues |

| Flexible and scalable implementation | Can be embedded into a single asset or scaled across and entire asset ecosystem creating a network of Edge AI intelligence |

| Historical trend analysis at the individual machine, device, or process level | Enables the prediction of future asset and process behavior based on AI-enabled analytics |

| Embedded process workflows that learn and evolve | Improves process performance while minimizing human intervention |

| Customizable, scalable and asset-specific security algorithms | Provides quicker detection and response to Zero-Day cyber-attack |

| All the above | Asset optimization, better control, reduced costs, higher OEE, improved security |

MicroAI Factory represents a significant step forward within industry 4.0. By bringing predictive manufacturing to reality, manufactures now have the means to revolutionize their production environments in ways that provide unprecedented levels of intelligence, predictability, efficiency and profit.