23 Sep MicroAI Factory™ – Optimizing Injection Molding Machines

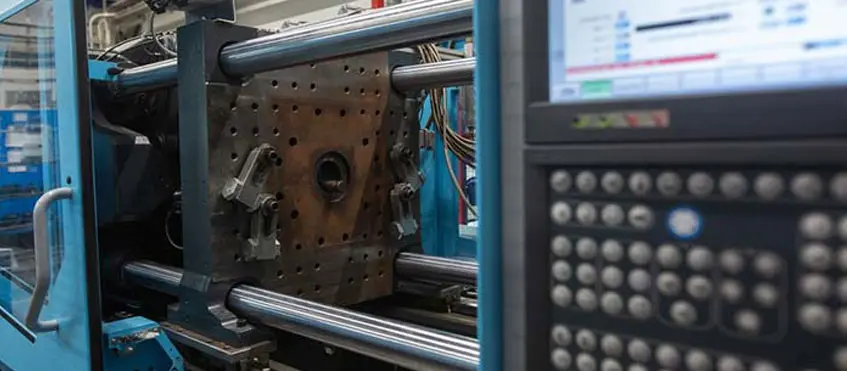

A recognized leader in the development of customized eye care products utilizes injection molding to mass produce the plastic components used in those products. The company needed an embedded AI solution that would fully optimize the performance of mission critical injection molding machines.

The Challenge – Injection Molding Asset Optimization

Like virtually every other manufacturing process, injection molding is being revolutionized by Industry 4.0 initiatives. Those initiatives have enabled a cascade of improvements in automation (machine and process). However, MicroAI’s customer wanted to go beyond mere automation by introducing next-generation intelligence into their injection molding assets. Embedded intelligence that would provide:

- Deeper Machine Observability: The ability to actively observe the critical performance parameters and health of an individual machine and/or groups of machines.

- Predictive Maintenance: A transition from preventive/reactive maintenance to a predictive state that would eliminate production loss resulting from unnecessary machine downtimes.

- Longer Asset Lifespans: The ability to extend the lifecycle of expensive capital assets via AI-enabled asset lifecycle management.

- Enhanced Cyber-Security: Attainment of a Zero Trust cyber-security state to provide protection against sophisticated Zero-Day cyber-attack.

- Improved OEE: The means to reach OEE (overall equipment effectiveness) scores of 80 to 85%.

All the above would need to be provided in a single, self-contained, platform that would provide quick implementation, low resource consumption, and solid ROI.

The Solution – MicroAI Factory

To meet the above challenges, MicroAI integrated its MicroAI Factory product into the customer’s existing factory ecosystem. MicroAI Factory is a factory-in-a-box solution that provides a self-contained asset management platform that utilizes breakthrough AI and ML (machine learning) technology to fully optimize the performance of machines and devices. Capabilities that include:

- Live Data Ingestion: Seamless and secure ingestion of data from individual injection molding machines as well as groups of machines. Live data that provides more intimate observability into machine performance.

- Predictive Analytics: Predictive algorithms that learn normal machine behavior, detect anomalies, and produce predictive insights into future problems and mitigations. Analytics that power a transition to molding machine predictive maintenance.

- Personalized Security: Ability to customize security protocols on a machine-by-machine level to accommodate specific conditions for individual machines or groups of machines. Injection molding machines are better protected from cyber threat.

- Real-time Visualization: A centralized visualization engine that provides continuous visualization into the performance, health, and security status of connected injection molding machines.

- Intelligent Workflows: The embedding and training of intelligent workflows that actively learn and evolve. Workflows that self-adjust to changing conditions, automate notification routines, and minimize human intervention.

- Rapid Deployment: Unlike other solutions that require extensive development resources, MicroAI Factory features no-code development while also eliminating the need for expensive data-labeling. MicroAI can be deployed and providing value within a matter of weeks.

The Impact

MicroAI Factory has enabled the client to dramatically improve the output, predictability, operational costs, health, and security of their injection molding machines. Specific impacts have included:

- Embedded AI has transformed injection molding machines from being human managed into being self-managed entities. This has created significant savings in labor and operational costs.

- Deep machine observability is providing the real-time insights and predictive analytics required to maximize injection molding performance. Performance anomalies and root causes are identified in real time. Injection molding machines are now maintained on a predictive basis

- Embedded security protocols have enabled the client to transition to a Zero Trust cyber-security state that provides hardened protection against ransomware and other types of cyber-attack. Threats can be detected in minutes vs hours or days.

- Real-time OEE monitoring provides real-time feedback on the effect of changes made to the injection molding machines and their support processes. As a result, the client has realized higher OEE scores across the entire injection molding infrastructure.

- All the above have combined to provide the client with…

- Increased productivity and quality of products produced on their injection molding machines

- Reductions in operational costs via transition to a predictive state

- Higher OEE scores that will continue to improve

- Operational excellence that creates new business opportunities

- A rapid return of their investment in MicroAI Factory