Manufacturing

Break the 75% OEE barrier with embedded and edge intelligence. Reaching true operational excellence in manufacturing requires achieving new levels of OEE (overall equipment effectiveness). MicroAI puts AI-enabled solutions to work on the OEE problem.

Schedule a Demo

Overview

Predictive Intelligence – Industry 4.0 to 5.0

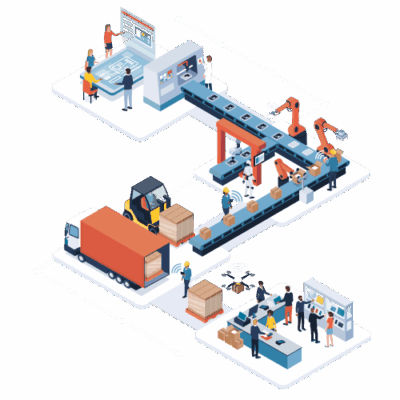

The next revolution in manufacturing will involve going beyond factory automation and into factory intelligence…from the automated factory to the predictive factory. Even in a highly automated production environment there exists intelligence gaps, both at the micro (individual asset) level and the macro (asset ecosystem) level. Closing these gaps is the next operational imperative.

Challenges

Manufacturing Intelligence Gaps

The fact that machines and devices are automated does not imply that they are smart. Automation does not equate to intelligence. Current intelligence gaps include:

The Solution

Enabling Predictive Manufacturing

MicroAI™ provides embedded and edge AI solutions for manufactures to evolve from mechanical automation to predictive intelligence. Breakthrough solutions that bridge the gap between automation and intelligence. The most comprehensive suite of capabilities that includes:

Asset-Centric Training, Monitoring, and Reporting

The creation of a centralized factory ecosystem of intelligence that provides customizable performance and health scores.

Real-time Performance Alerts

AI that is embedded into the asset endpoint providing deep observability into real-time asset performance.

Historical Trend Analysis

The ability to transition from preventive to predictive analysis and to maximize asset output.

Intelligent workflow integration

Process automation via workflows that learn and evolve…intelligent workflows at the edge.

Endpoint cyber-security

Personalized asset security that provides hardened protection against sophisticated cyber-threats (zero-day, ransomware, etc.).

Simple integration

The ability to localize training and inferencing at the edge, without labeling data, allowing for full customization of AI models in a short amount of time.

Benefits

Manufacturing Excellence Redefined

The evolution to the predictive factory will have far-reaching implications. By utilizing MicroAI’s suite of embedded and edge AI product platforms, manufacturers will reach levels of operational performance that had previously been unattainable. Advancements will include:

-

Improved OEE

Improvements in OEE performance from the current standard of 70% to a new standard of ~ 85%.

-

Holistic Visibility

Non-siloed, at-a-glance, perspective of real-time performance and events across the entire factory floor.

-

Improved Resource Allocation

Edge AI-enabled intelligent workflows reduce the reliance on human intervention and ensure optimum execution of processes.

-

Increased Production

Predictive maintenance eliminates downtimes related to unnecessary maintenance activities and/or unforeseen malfunctions.

-

Enhanced Security

Embedded and edge security algorithms that provide more robust cyber protection and that shorten detection and reaction times (detection in seconds instead of hours/days).

-

Longer Asset Lifespans

Real-time asset health monitoring, process-driven mitigation actions, and predictive maintenance capability all combine to extend the lifespan of expensive assets.

Improved OEE – The Consequences

- A 15% improvement in OEE can equate to a 17% increase in productivity. An operation producing $60M worth of products can increase their output to ~ $70M.

- Improved OEE equates directly to a reduction in asset maintenance costs. Unnecessary maintenance is eliminated via the implementation of predictive maintenance.

- Higher OEE scores translate to improved quality of the products being produced. Machine and device performance are more reliable and more predictable.

- Production costs are reduced. This results in improved product pricing as well as healthier bottom lines.

You've read about it.

Now see Agentic AI in action.

Smarter Decisions. Faster Growth. Ready to take the lead?

Book a live demo

See what’s possible with Agentic AI.

Talk to AI experts

Let's collaborate on what you can build.

Explore Turnkey AI Agents